Particle size analysis¶

For the particle size analysis, we're going to use the following equipment,1 which utilizes the Laser Diffraction method:

Measurement principle¶

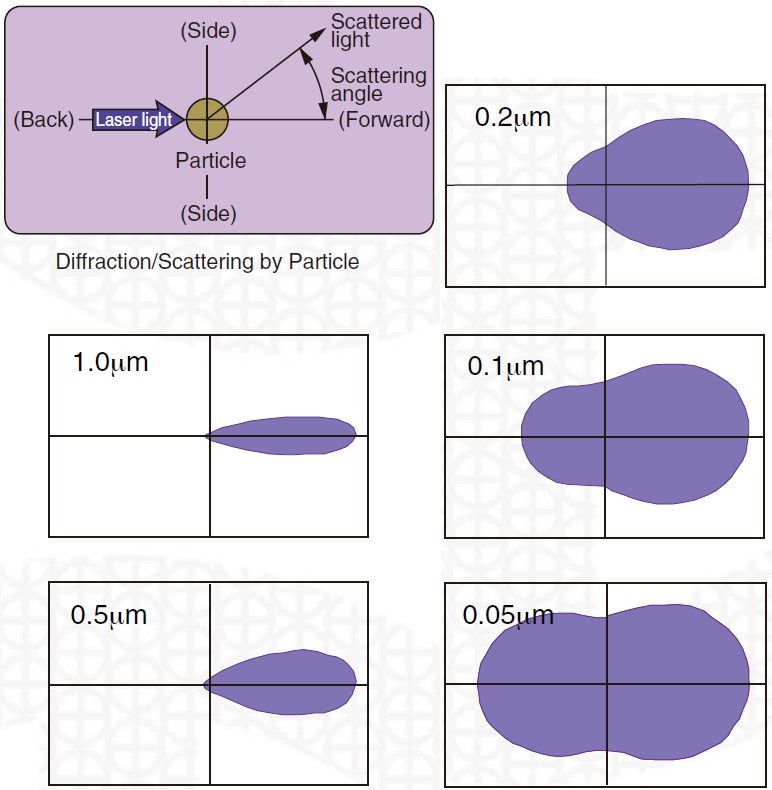

When a particle is irradiated with a laser beam, light is emitted from the particle in every direction. This is “scattered light”. The intensity of the scattered light varies with the scattering angle and describes a spatial intensity distribution pattern. This is a “light intensity distribution pattern”. If the particle diameter is large, the scattered light emitted from the particle is concentrated in the forward direction (i.e., the direction of the laser beam), and fluctuates intensely in a small angular range. Compared to the light emitted in the forward direction, the intensity of all other light is extremely low. As the particle diameter becomes smaller, the pattern of the scattered light spreads outwards. As the particle becomes even smaller, the intensity of the light emitted to the side and backwards becomes higher.

In this way, then, there is exists a one-to-one correspondence between the particle diameter and the light intensity distribution pattern. This means that the particle diameter can be ascertained by detecting the light intensity distribution pattern.

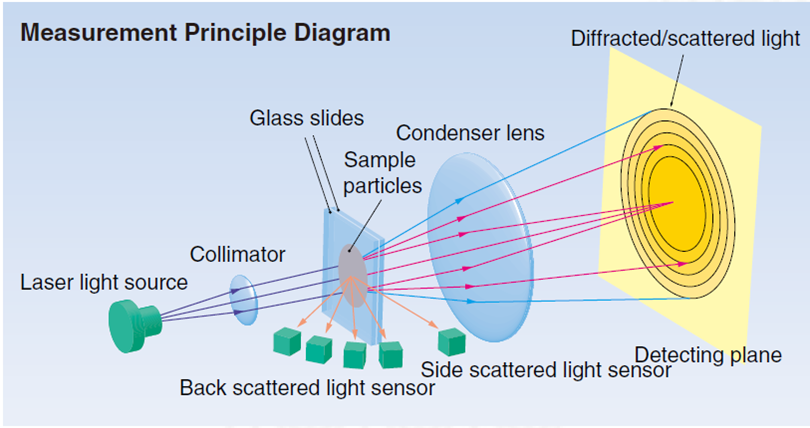

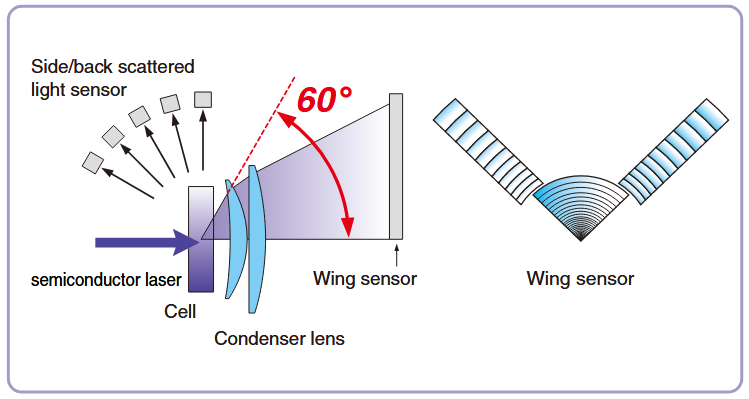

The scattering pattern dictates the sensor arrangement:

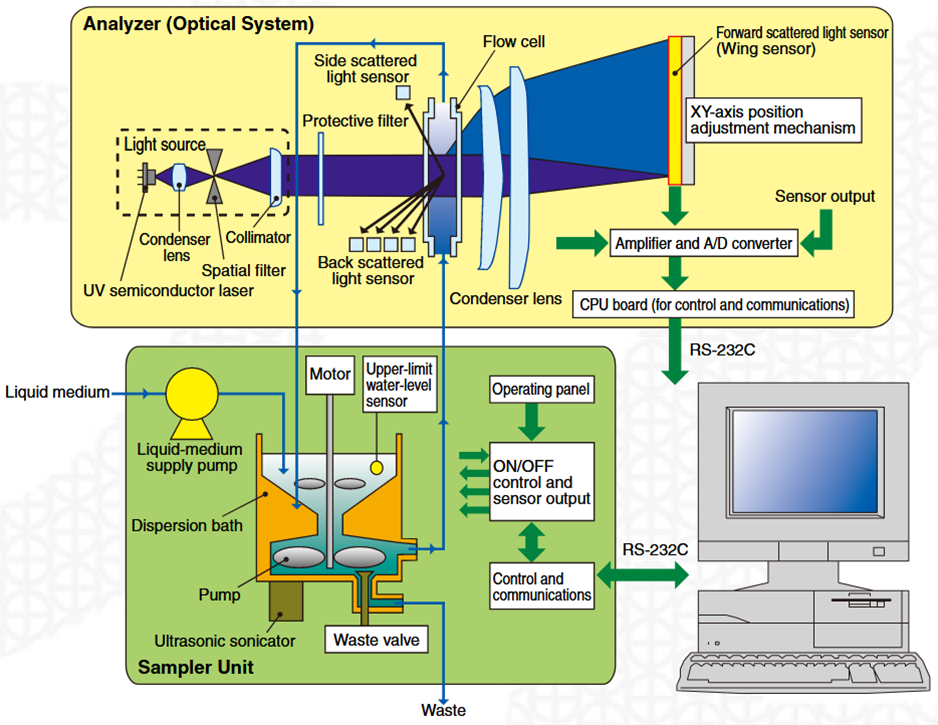

Schematics¶

- The particles, which are dispersed in a liquid medium, are circulated between the flow cell and the sampler dispersion bath. The flowcell is set in the measurement unit, while measurement is performed.

- The dispersion bath incorporates a stirrer and an ultrasonic sonicator.

- The dispersed suspension is delivered to the flow cell by a pump.

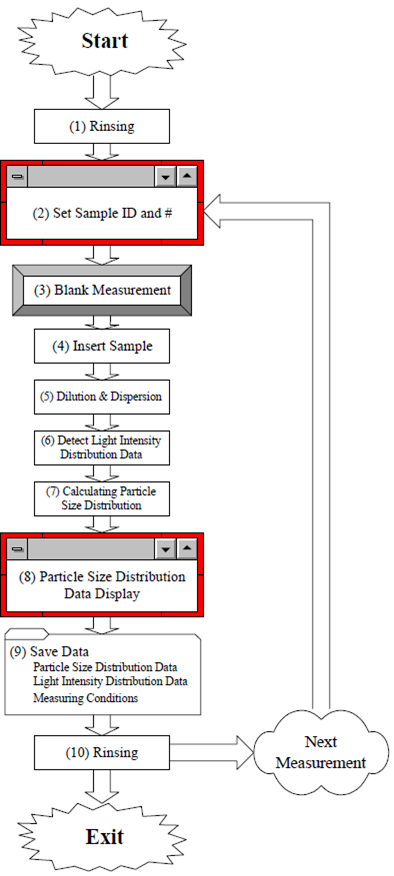

Measurements¶

Limitations¶

Measurement range: 10 nm (0.01 μm) to 300 μm

For the most precise measurements, the particles should be:

- of the same composition

- spherical

- preferably, with known complex refractive index

Another limitation is that the algorithms used in laser diffraction analysis seem to be proprietary and may differ between the setups.